Plastic developed from waste biomass

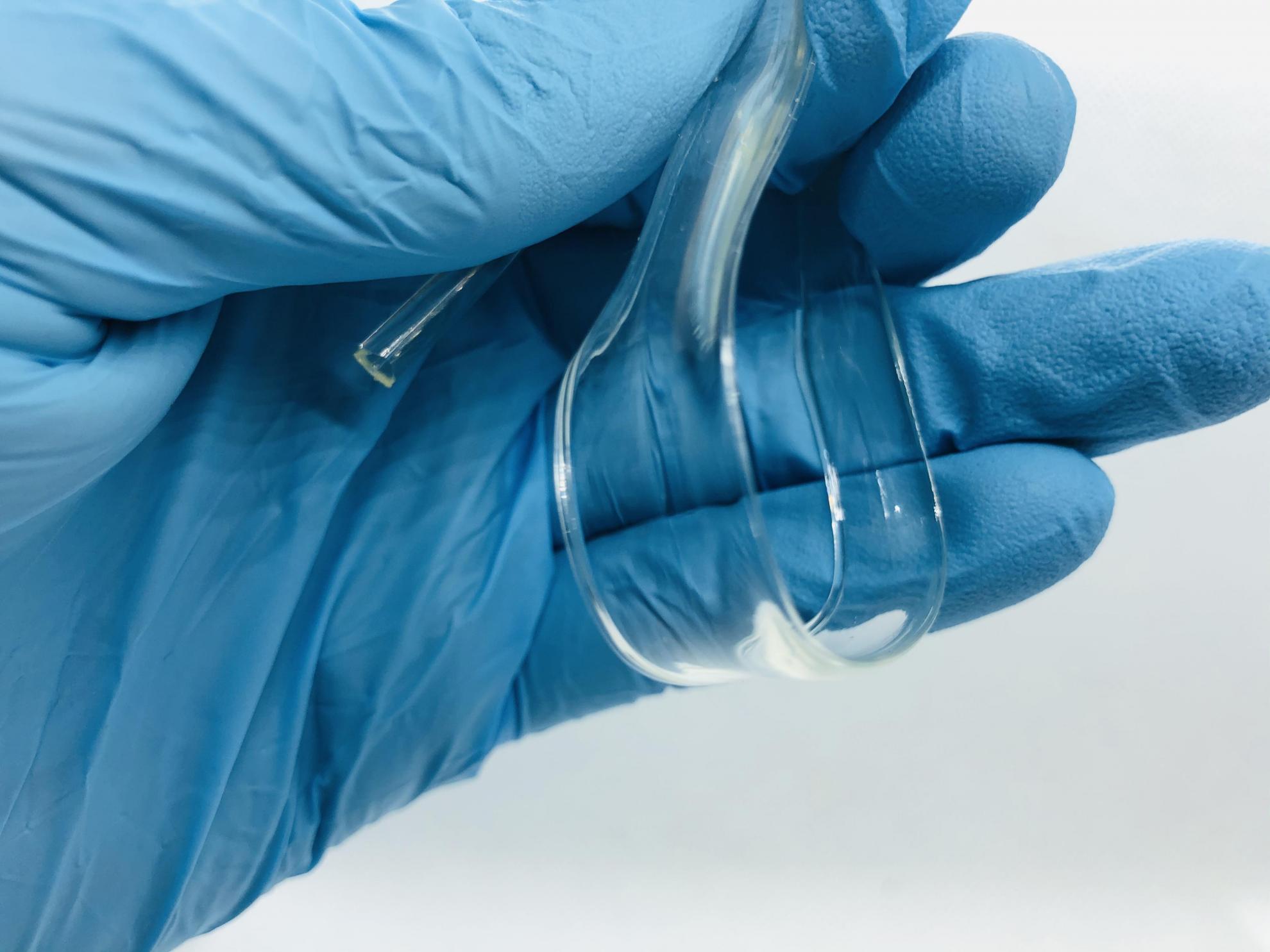

The bioplastic is highly flexible and transparent.

Scientists at EPFL in Lausanne have developed a new PET-like plastic from non-edible plant parts. The new product can be used for food packaging and other applications.

Scientists around the world are working on degradable or recyclable polymers made from non-edible plant material, referred to as 'lignocellulosic biomass', to address the growing crisis of plastic pollution. A team from EPFL Lausanne’s School of Basic Sciences are confident they have found an ideal solution.

A more environmentally friendly plastic

According to a press release, the new plastic meets the criteria for replacing several current plastics while being more environmentally friendly. The characteristics of the new product are similar to that of regular PET plastic: it is a tough, heat-resistant material that provides a good barrier to gases such as oxygen. Due to its structure, the new plastic can also be chemically recycled and degraded into harmless sugars in the environment. PET, in contrast, does not decompose and is made from petroleum products.

We basically just 'cook' wood or other non-edible plant material, such as agricultural waste, in low-cost chemicals to make the plastic precursor in one step.

Technique based on discovery in 2016

The technique is based on a discovery published by Prof. Luterbacher and his colleagues in 2016 that the addition of an aldehyde, an organic compound, can stabilise plant material parts to prevent their destruction during extraction.

By keeping the sugar structure intact within the molecular structure of the plastic, the researchers developed a chemistry that is much simpler than current alternatives.

From packaging to 3D printing

The plastics produced can potentially have a wide range of uses, say the researchers: from packaging and textiles to medicine and electronics. The team have already developed packaging films, fibres that can be spun into clothing or other textiles, and filaments for 3D-printing.

The findings of their work, which is funded by various Swiss organisations such as the Swiss National Science Foundation, as well as the European Research Council Horizon 2020 programme, was published in Nature.